The printed circuit board (PCB) is a revolutionary invention. Its importance to modern electronics is tantamount to the significance of the wheel in car production. Also, like the wheel, when something becomes so widespread that we mistakenly treat it as commonplace, we take for granted how a singular spark of brilliance forever changes the entire world.

Along with the introduction of the PCB, we have seen transformative advancements in manufacturing for PCB assemblies and manufacturers perfecting the process of turnkey solutions.

In addition to exploring what turnkey PCB assembly is, we’ll discuss the value of these solutions and why partnering with the right manufacturer makes all the difference in quality, cost, and turnaround.

What Is a PCB?

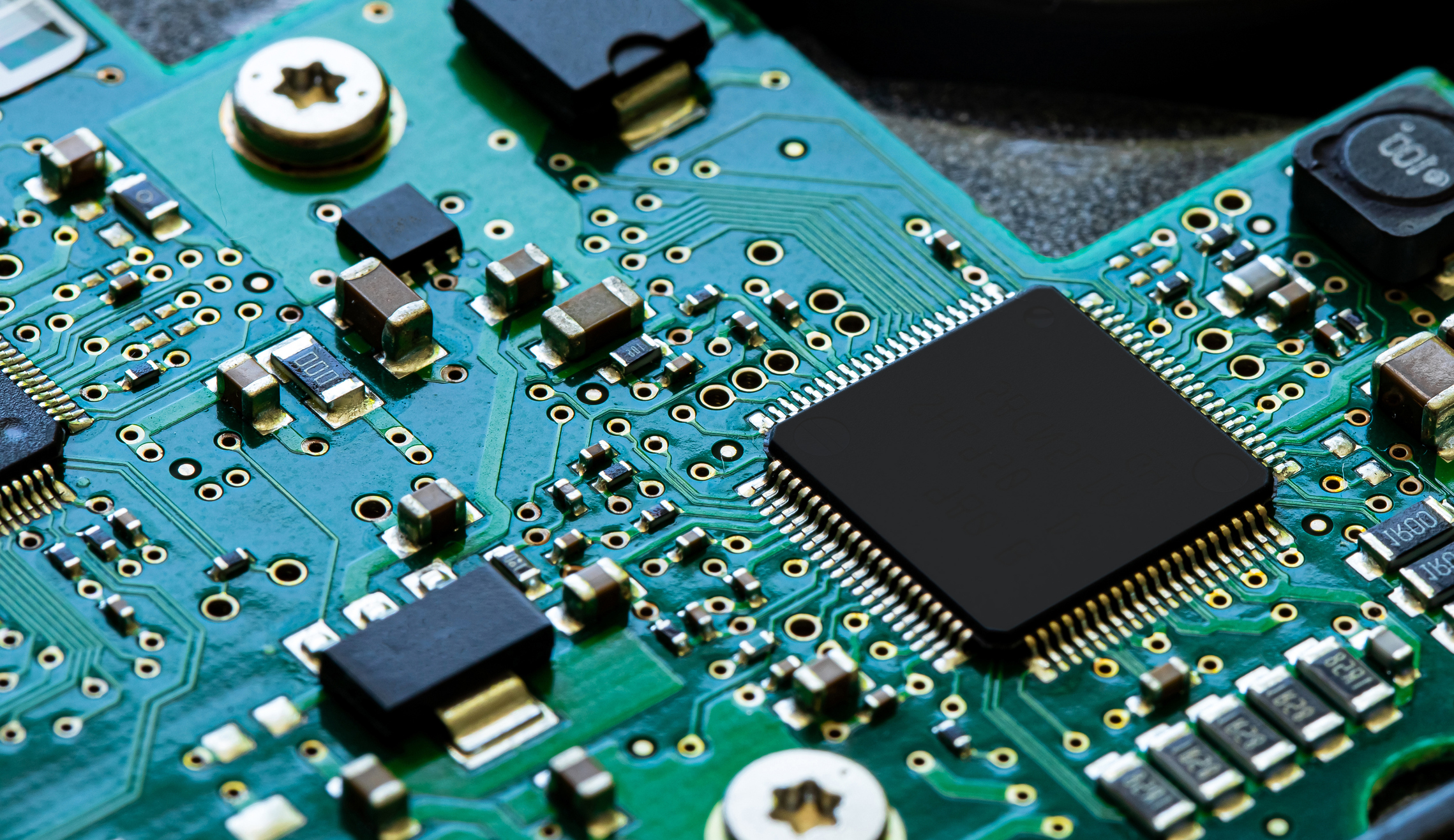

Printed circuit boards (PCBs) are used for wiring component circuitry together on a thin board, usually made of fiberglass, composite epoxy, or similar materials.

Prior to PCBs, complex electronics were all wired by hand, and all components were directly connected by wires soldered together. The fundamental concepts of different electronic devices were intricate and sophisticated but costly and laborious to produce.

In 1925, the American inventor Charles Ducas came up with the initial inspiration of a printed wire. This concept was mastered by the first official working PCB in 1943 by an Austrian engineer named Dr. Paul Eisler.

With a PCB, complex wiring schematics can be etched or printed into a board, saving an immense amount of time, money, materials, labor, and space. A modern PCB can manage the equivalent electronics that would have taken up an entire building in the 1940s at a fraction of the price.

For instance, the ENIAC computer completed in 1946 occupied 1,800 square feet, using over 17,000 vacuum tubes for processing, while the modern smartphone’s microchip has around 100,000 times the processing power of the computer that assisted navigation for the Apollo missions.

What Is a PCB Assembly?

PCB assembly can refer to two related concepts:

- A circuit board with all of its components completely installed

- The act of populating components for that circuit board

What Is Turnkey PCB Assembly?

Turnkey means that everything involved in manufacturing a product to completion is included. Like turning a key to start a car, a “turnkey” solution means that the product manufactured is finished and ready for the user to operate.

Turnkey PCB assembly means a manufacturer is able to manage every aspect of creating a printed circuit board, propagating it with the components it is designed to be used with, and providing the finished product fully tested and shipped.

What Is the Difference Between PCB and PCB Assembly?

A PCB is a printed circuit board without any components attached. A PCB assembly, also called a PCBA, is a PCB with all of the components installed.

The PCB contains all of the wiring paths integrated into the board, but until the components are assembled onto the board, none of those connections become active.

PCB and PCBA can be described as two stages of the same manufacturing process, where the PCBA is the completed stage.

What Are the 5 Main Different Types of PCB Assembly?

PCBs come in all shapes and sizes. They are used in everything from computer motherboards to medical devices, smartphones to everyday appliances. Today, any device that requires wiring connections is likely designed on a circuit board.

There are five main types of PCBs.

1. Surface Mount Technology (SMT)

SMT assemblies are used to mount components directly on top of the surface of a PCB. SMT PCB assemblies make it easy for a wide range of components and devices to fit in place without requiring extra wiring and, in some cases, without the need for soldering.

For example, Schott Magnetics manufactures surface mount inductors and transformers, also known as surface mount devices (SMDs), that can be used with PCBs mounted directly to the surface in place of wired leads.

2. Through-Hole Technology (THT)

THT assemblies allow component leads to connect to the PCB by inserting the leads through drilled holes. Schott also makes custom inductors and transformers for through-hole connectivity.

3. Mixed Technology Assembly

Mixed technology PCB assemblies are a combination of SMTs and THTs, offering flexibility for how a design is able to connect to other components.

4. Ball Grid Array (BGA)

When a PCB is incredibly small and intricate, a BGA can be useful to attach an extremely large number of pins. Microprocessors are a common example of a BGA assembly PCB.

5. Rigid-Flex PCB

A rigid-flex PCB assembly may also be called a flex-to-install or dynamic flex PCB, and can be created for use in numerous different designs. They use a combination of flexible and rigid substrates in each case.

What Are the Main Benefits of PCB Assembly at a Single Facility?

When you are able to fully assemble your PCBs at a single manufacturing facility, you are dealing with fewer contacts, which also means fewer conversations and less need for coordination between multiple facilities.

With every step of manufacturing coming from a single operation, it is the manufacturer’s responsibility to source all of your component parts, run quality assurance, and ship the final assembled products.

How Much Does the Average PCB Assembly Cost?

The cost of PCB assembly varies widely depending on how complex the design is and the amount of labor involved.

PCBs are used everywhere—from mass-produced consumer products to small-run boutique audio equipment. Virtually every industry relies on PCBs. The scale of operations, production size, and complexity of circuitry all play a role in the cost to manufacture and assemble PCBs.

Pricing is often based upon the amount of circuitry involved in each square inch for the device but is also heavily influenced by how many are produced since larger quantities can cut individual costs down considerably.

Cost-Savings Using a Mexico Manufacturing Facility

One of the determining factors on cost is the ability to have PCBs manufactured in Mexico.

When factoring in labor costs, affordable shipping rates, fast turnaround, and favorable trade deals providing tariff-free imports, the best prices for high-quality PCB assembly come from Mexico.

For example, in 2023, Mexican manufacturing workers earned $3.90 per hour, compared to the labor costs in China at around $6.50 per hour. In the US, as of August 2023, manufacturing wages averaged $26.70 per hour.

This is why SCHOTT Magnetics can offer our clients full turnkey PCB assembly for transformers

at the highest quality with virtually any quantity—and with fast turnaround times.

Our production facilities in Mexico have the following certifications:

- ISO 9001:2015 Quality Systems Certified Facilities

- EN 60950/UL 60601 CSA, UL, and Safety Agency Certifications and Support

- ITAR Registered – US

- RoHS, Pb Free & Conflict Materials Compliant

Come to Schott Magnetics for Your Transformer PCB Assembly Needs

At SCHOTT Magnetics, we pride ourselves on being the go-to manufacturer for industry leaders in every field, from telecommunications to aerospace. If you are looking for the best prices and fastest turnaround for transformer PCB assemblies, get in touch with our experts today.